CLASSIFICATION OF PLASTIC BAR CHAIR

Classification of plastic bar chair used as concrete spacer in the reinforced concrete structures.

Post date: 02-08-2017

13,200 view(s)

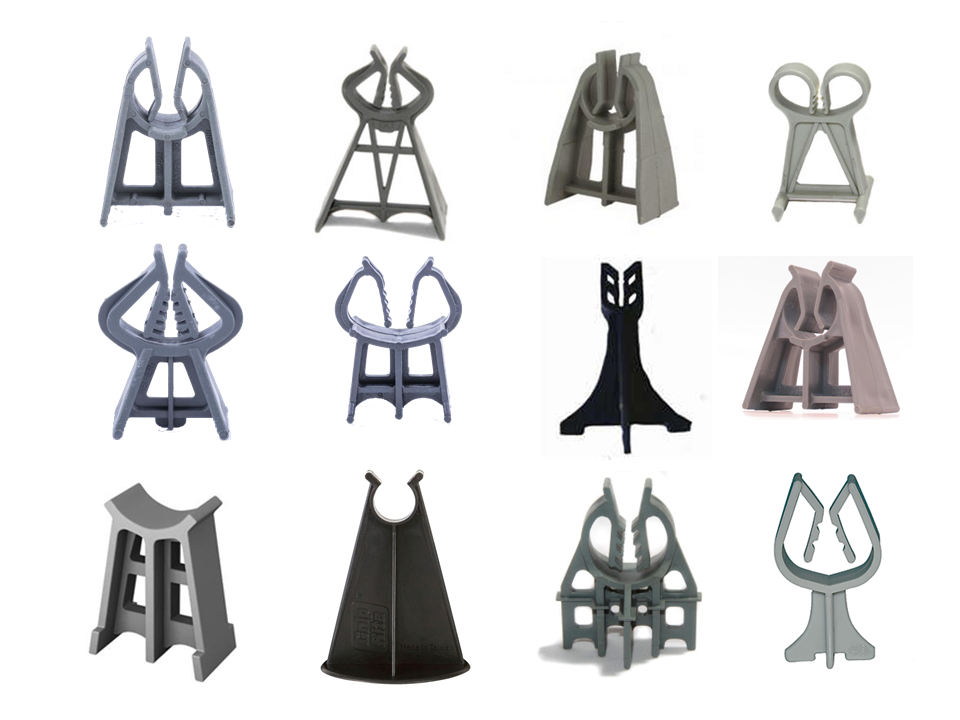

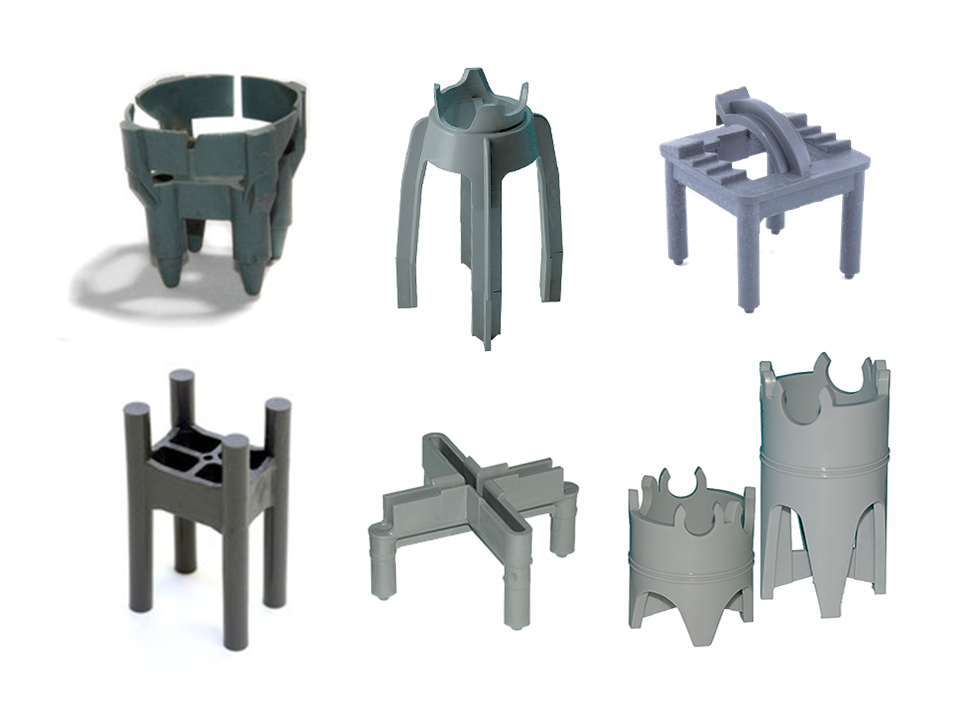

The products of plastic bar chair are multiform depending on the design from manufacturer. Based on their specifications, they can be classified as below:

1/ Cone Bar chair: The products have the cone shape with a base to stand on the surface. Therefore the bar chair support the rebar stably on the ground or stone base without tearing the plastic sheet under concrete slab, if any. Cone bar chair is specially suitable for top steel mesh layer. Depend on the design, on the top of bar chair might have the clips to keep the steel rebar after installation.

2/ ”A shaped” Bar chair: This kind of product has the shape of letter A, connecting the steel bar on its top and having an expanded base to ensure a stable standing. “”A shaped” bar chairs have small connection of their bases on the formwork, so they are suitable only with the firm formwork. This kind of product is generally designed with clip on the top to hold the steel rebar. With the clip, the “”A shaped” bar chair can be placed also in horizontal position for the stirrup of beam/column or rebars of wall structures.

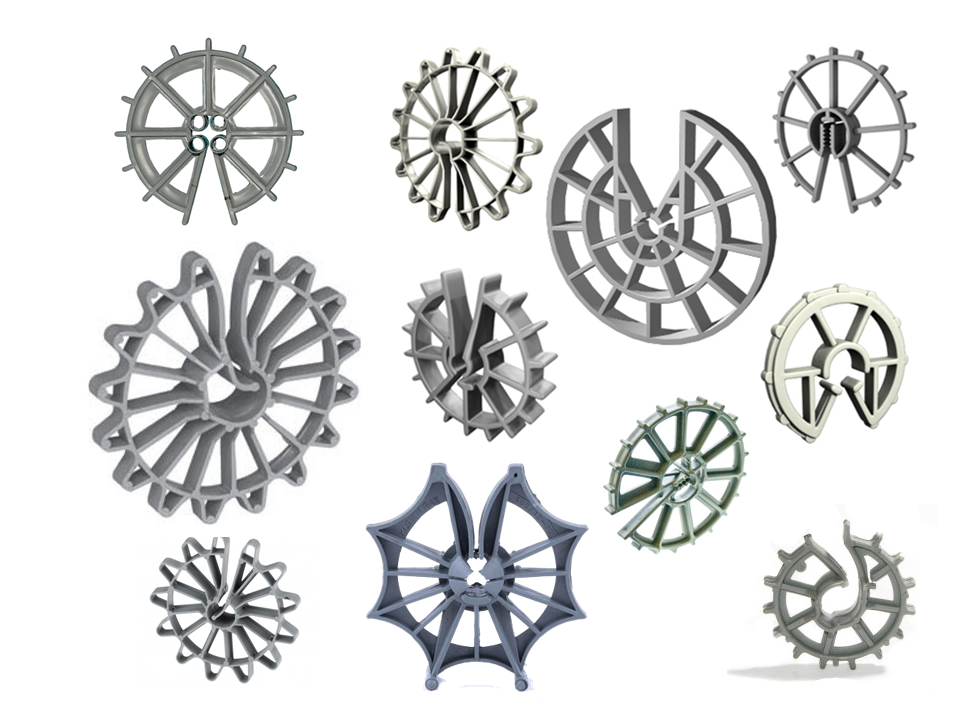

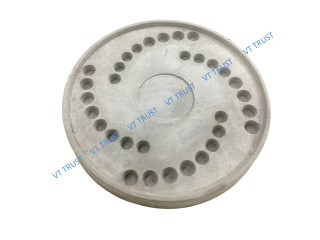

3/ Wheel chair: The products have circle shape with a hole in the center for holding the rebars The distance from the side of center hole to the wheel perimeter is equal to the designed concrete cover. Wheel chair is especially suitable for the horizontal and vertical rebars of column, wall reinforcement. Wheel chair bears a significantly small force only in the horizontal direction. Thank to clip details, the chair cannot be slipped, fallen during concreting work. Even though it can be turned during the construction, wheel bar chair still ensure the concrete cover thickness will be unchangeable. Wheel chairs might be used to support the rebar arranged in the horizontal plane but they cannot bear the heavy load from above.

4/ Heavy Duty Wheel chair: Being designed as normal wheel chair but Heavy Duty Wheel Chair has its large width and made of strong plastic so it can bear very well the forces perpendicular to the wheels. These products are usually used in the bore piles or large structures.

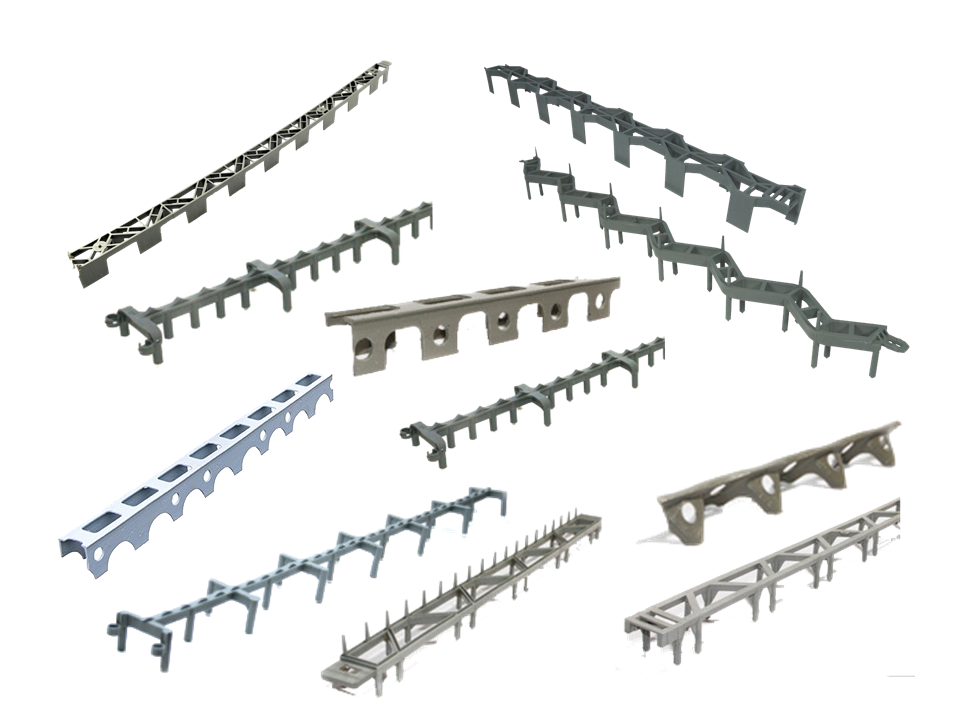

5/ “Bar shaped” chair: The products have the bar shape approximately 1-2m. The chairs use for the bottom mesh layer of slab (horizontal plane) or wall mesh (vertical plane). The height of chair is the required concrete cover thickness, The continous side of chair will be placed towards inside the structure and contact with steel rebar, while the other side contact with the formwork on the legs or short sections in order to minimize the contact of bar chair with the outside environment. The advantages of this kind of chair is its high stability and quick installation.

6/ Frame bar chair: The products have the characteristics and use similar to the “bar shaped” chair products but they are designed to form the closed frames of rectangular, circular, annular shapes.

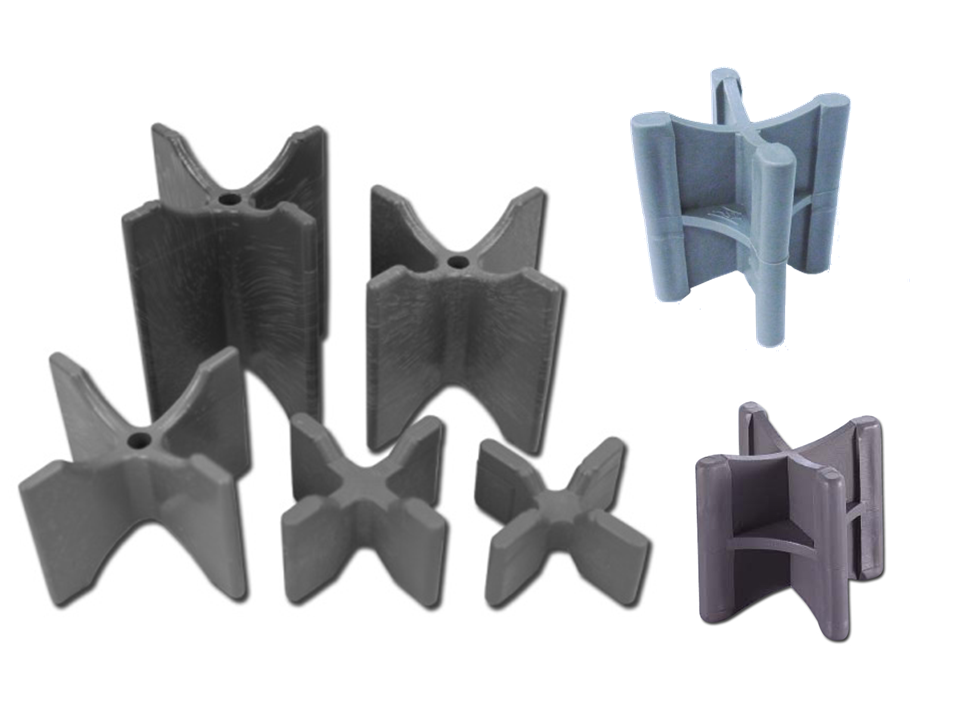

7/ X bar chair: Products are designed in the point support type. Due to the X shape, this kind of chair is very stable, impossible to be turned over during construction. The connection to the formwork is very limited so it is suitable with the firm formwork only.

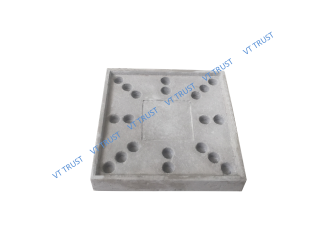

8/ Four (4) sides Bar chair: The products have the rectangle shape with the concave sides for placing the steel rebar.With two different dimensions of two sides, this kind of product can form at least 2 different concrete cover thickness depend on their installation. The product can include the holes for wiring. This kind of bar chair has a significant weak stability. It is suitable with firm formwork and limited movement of steel cage/mesh during construction.

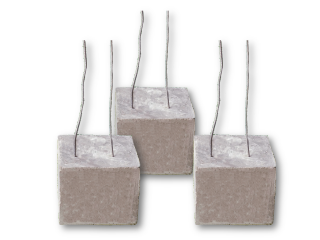

9/ Flat base bar chair: The product has the flat base and high load bearing capacity. They are especially suitable with the loose foundation such as soil, stone.

10/ Four (4) legs bar chair: The product really has the shape of chair with 3-4 legs which contact the formwork and support the above steel rebar. Similar to the chair of point type, this kind of chair is suitable only for firm formwork. Due to their weak load bearing capacity, this kind of product is usually use for steel mesh of slab.

11/ Stackable bar chair: This kind of product is similar as “4 legs bar chair” but they are specially designed for their stackability. Due to this advantage, the bar chair can be used for both bottom and upper mesh layer. However, their load bearing capacity is low, similar as of “4 legs bar chair”.

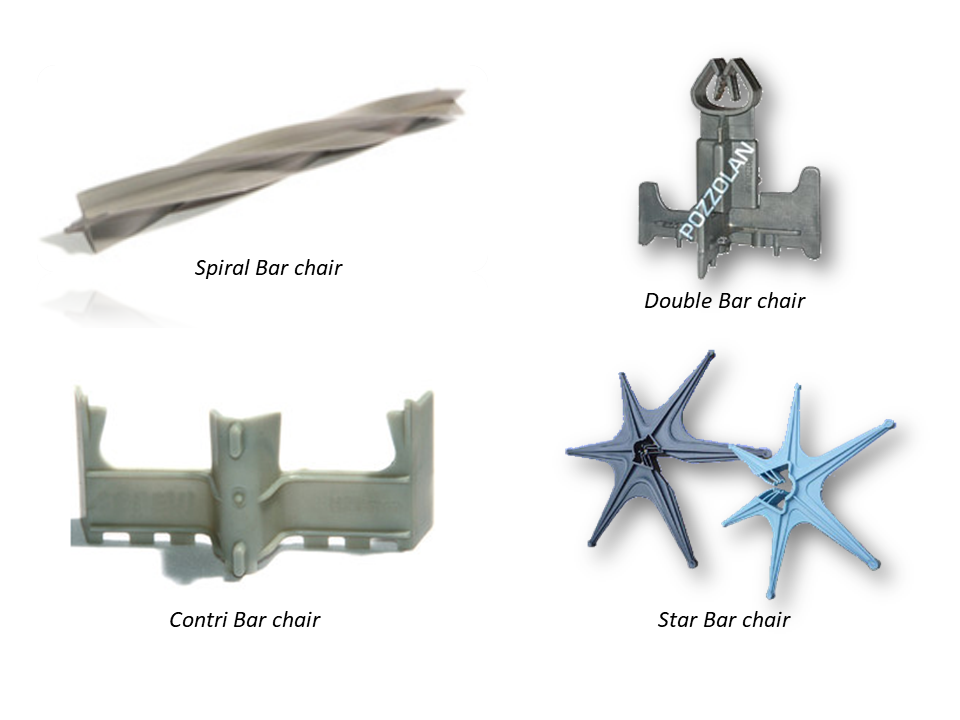

12/ Special bar chair: Some products are specially designed such as spiral bar chair for bottom mesh, 3 sides bar chair, double bar chair, star bar chair... Due to their limited application, these bar chair products are not commonly use.

Click the following items for consultant or learn the products and contact us.

Send your comment